Fork

light barriers

with IO-Link

Fork

light barriers

with IO-Link

More flexible, faster, more precise,

simpler and even more rugged –

with the exact same size.

For decades, di-soric has been developing fork light barriers that set new standards.

We are now offering the fork light barrier 4.0 with an innovative dual operation concept, either over IO-Link with the configuration of all sensor functions including 4 selectable sensor modes or through easy manual switching point adjustment with a potentiometer.

No application gets left out

Due to the variety of sizes and formats, the high resolution and fast reaction time, our fork light barriers make optimal, process-reliable solutions possible - always tailored to the application and the installation space available.

Application-specific configuration instead of specific hardware

Instead of keeping various forks on hand for different applications, you can save the application-specific configuration, load it into the fork as needed or select the necessary operation mode and get started right away. Device swapping works just as easily.

- All standard applications

- Applications in areas with high standards with respect to hygiene and cleanliness

- Applications with higher demand for power reserve

- High-precision applications – Stainless steel variants available

Advantages and features

of all series

Dual operating concept

Via 2 potentiometers and IO-Link – Selection of the sensor mode or teach-in over IO-Link

Very easy operation

Adjustment of the switching point and NO/NC changeover using a potentiometer

Backward compatible

with previous di-soric OGU models in terms of design and M8 connection

IO-Link - Ready for digitization

Sensor identification, configuration and diagnosis, remote maintenance option, quick exchange of sensor due to parameter storage in IO-Link master

Ready-to-run

4 preconfigured sensor modes:- Standard

- High Resolution

- Power

- Speed

Even more rugged design

Powder-coated metal housing* with full encapsulation and IP67, compatible with all OGU and standard mounting options

* OGU 005, 061, 071, 091 in anodised aluminum housing

Ideal for Industry 4.0

System designs

Ideal for Industry 4.0

System designs

Fork light barriers with IO-Link

Field devices with an IO-Link interface feature on-board digital intelligence. This allows them to swap position, process, status and device information easily in a digital format. The sensor can be configured directly using the IO-Link master. Settings can be applied to the sensor directly via drag and drop by means of a control panel.

Even device replacement can be carried out quickly and easily with IO-Link and data storage in the master using the Smart Sensor Profile, without any expert knowledge.

4 sensor modes through IO-Link for maximum flexibility

Standard

Switching frequency: 5000 Hz

Reproducibility: 0.02 / 0.01 mm¹

High Resolution

Resolution for small parts detection improved by 30%

Power

Increased transmitting power and thus increased function reserve

with reduced sensitivity to dirt

Speed

Fast operation at up to 14000 Hz switching frequency

Supportive, smart IO-Link functions for fork light barriers

Diagnostics

Qualitative and quantitative- Analysis of process stability and teach-in quality (qualitative)

- Current process values, min/max, teaching and threshold measured values (quantitative)

Easy maintenance

- Device swapping without manual intervention or specialized knowledge thanks to IO-Link 1.1 with data storage in the master

- Smart Sensor Profile – fully compliant with standards

¹ Fork light barriers OGU / OGUL with fork openings up to 80 mm

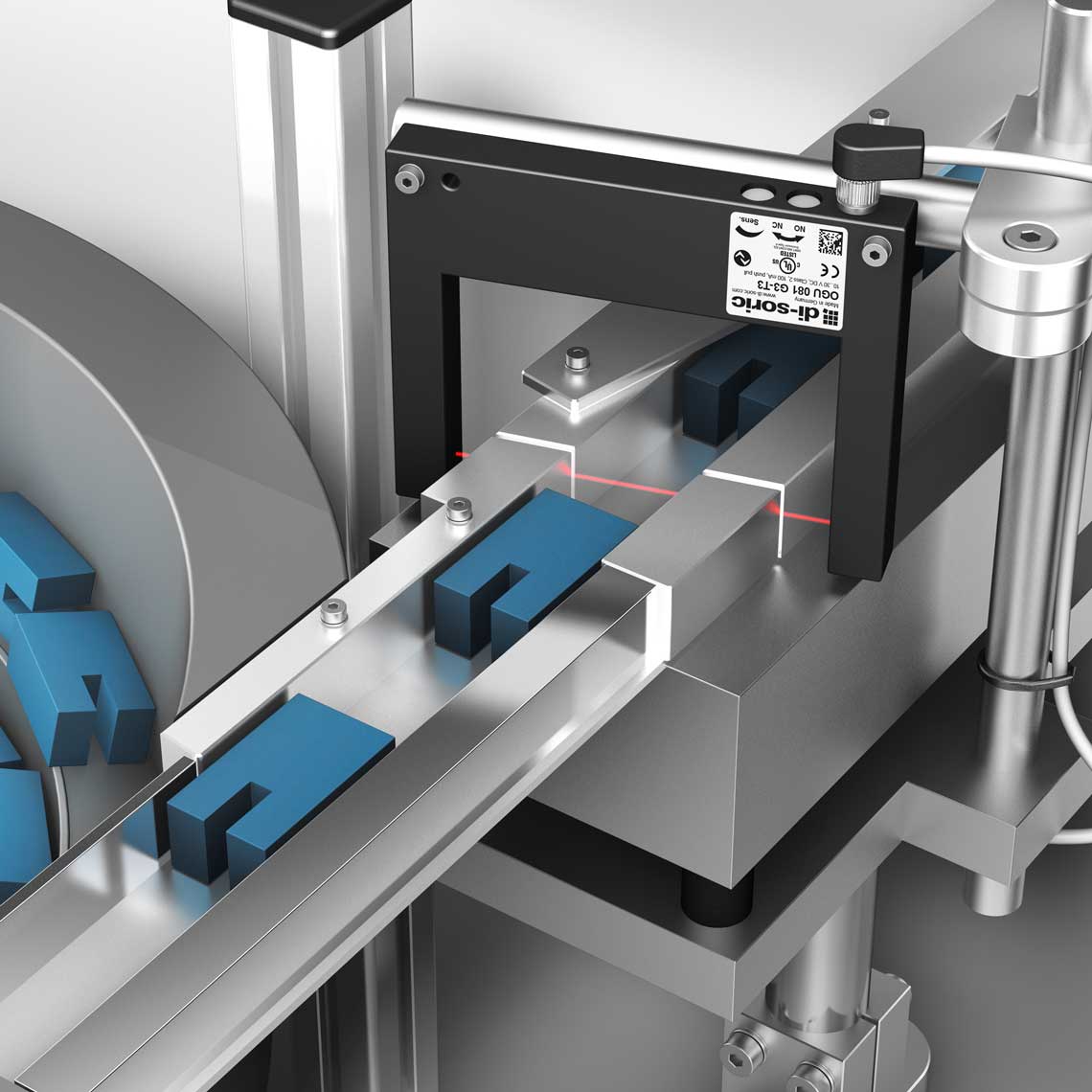

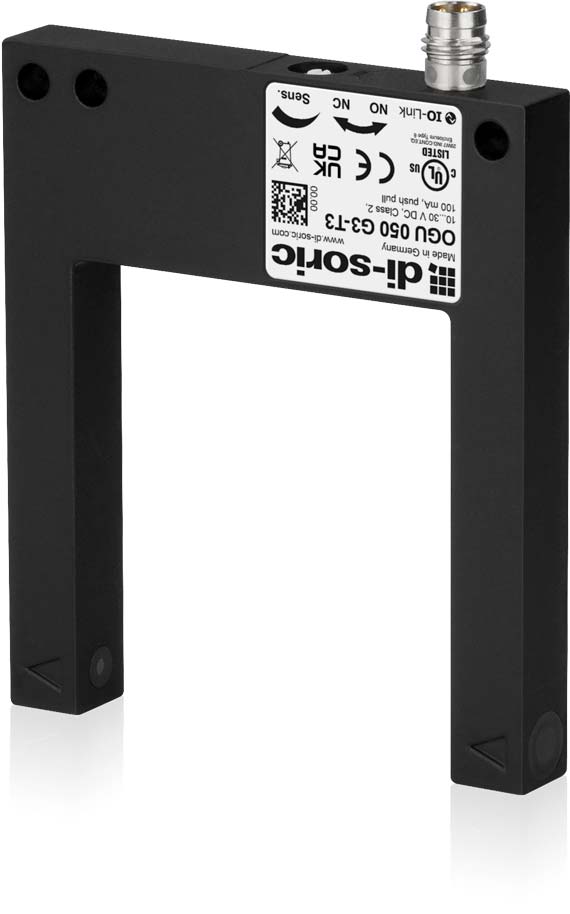

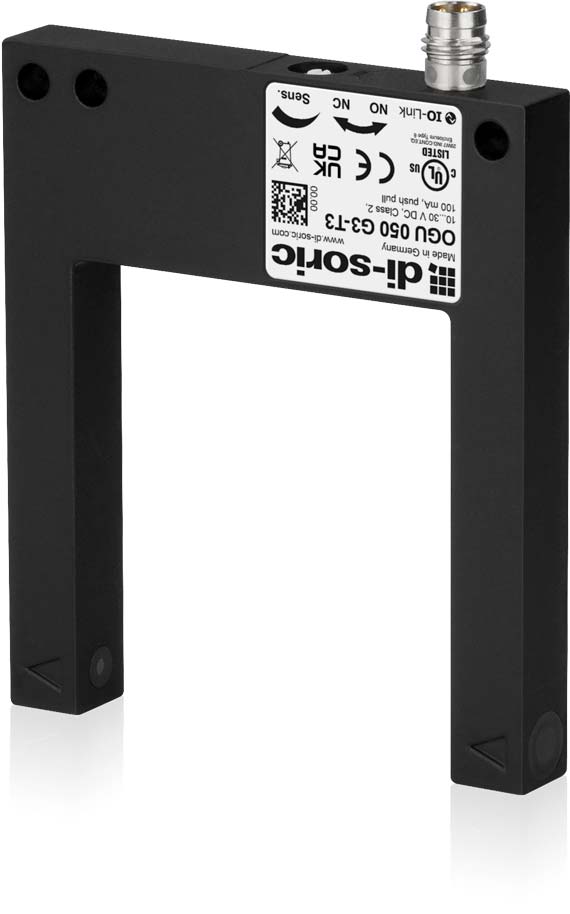

OGU – Our medium format.

Standard in the finest gradations.

High resolution combined with amazing speed and precision –

with red and infrared LEDs – without lasers.

Fork light barriers are the preferred choice wherever small objects or object positions must be detected quickly, precisely and independently of their surface. High switching frequency and maximum resolution means that our medium formats are capable of reliably detecting rapid motion sequences, even of very small parts with diameters starting from 0.2 mm.

- The outstanding reproducibility standard of 0.02 mm enables the extremely precise position recognition of objects.

- The OGU fork light barriers, available as red-light or infrared-light variants, achieve virtually the same level of performance as laser light barriers in terms of resolution and reproducibility.

- The outstanding reproducibility standard of 0.02 mm enables

the extremely precise position recognition of objects. - The OGU fork light barriers, available as red-light or

infrared-light variants, achieve virtually the same level

of performance as laser light barriers in terms of

resolution and reproducibility.

Fork openings in increments of 10 mm:

30 . 40 . 50 . 60 . 70 . 80 . 90 . 100 mm

We have exactly the fork you need if you want to achieve maximum performance within a minimal installation space.

In contemporary mechanical engineering, design is playing an ever greater role – our slim OGU fork light barriers in the medium format are available in increments of 10 mm and are suitable for the most diverse machine designs. Thus, you can always find the optimally matching fork light barrier for your planned design.

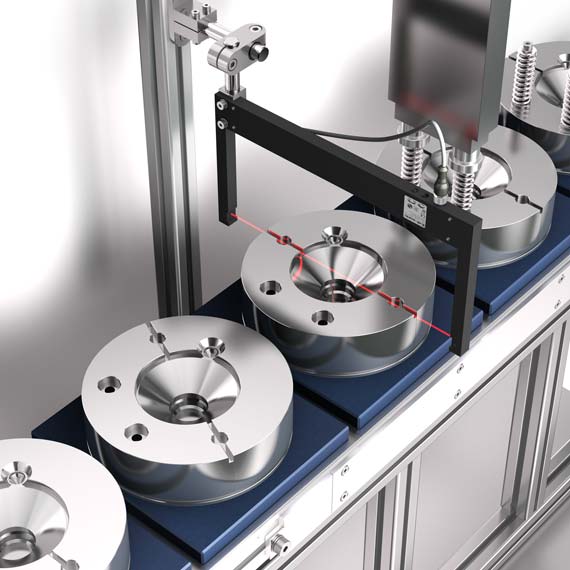

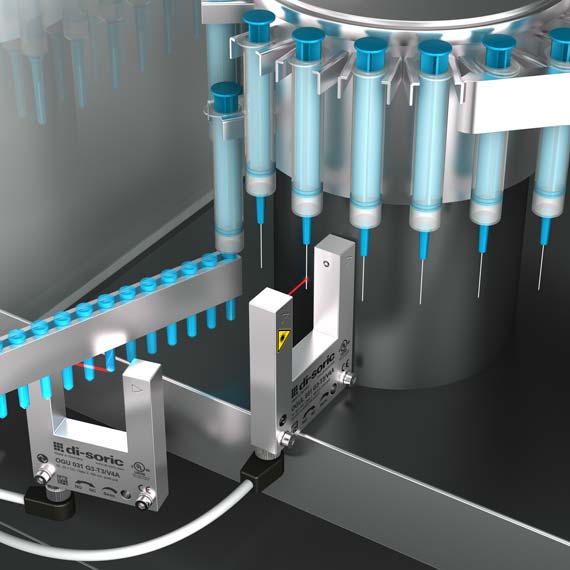

Application examples

OGU medium format

OGU – Our small ones:

5, 10 and 20 mm.

Super-fast on the short distance.

So small and yet so tough –

Speed up your machines.

The OGU 005 and 010 are not only our smallest fork light barriers but also our fastest: With a switching frequency of up to 14,000 Hz, they are among the fastest forked light barriers worldwide.

Install our fork light barriers, even without the potentiometer being accessible, and simply configure using IO-Link – a greater amount of space cannot be conserved.

Application examples

OGU small format

OGU – Our large sizes.

Is it alright if it’s a bit over?

Here you go! – Where others have given up long ago,

we will even add a bit: 120 . 170 . 220 . 250 mm

The perfect alignment of transmitter and receiver in our large fork light barriers is assured – as is the visible red light, which further eases the setup of your application.

However, the fact that even at such fork openings, small parts in the millimeter range are precisely identified with a reproducibility down to 0.03 mm, makes them excellent.

Application examples

OGU large sizes

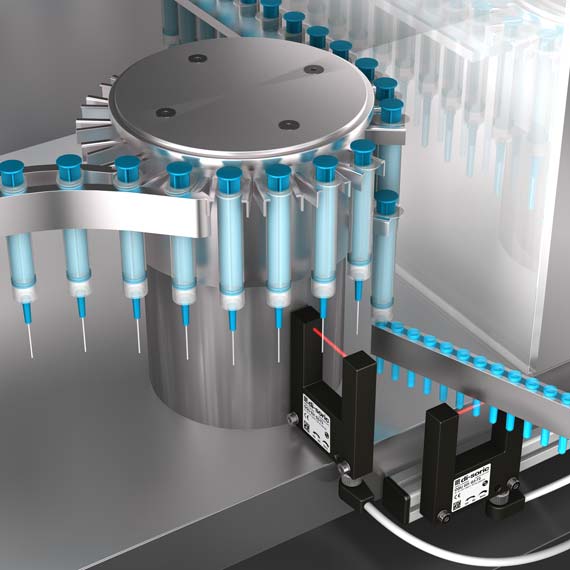

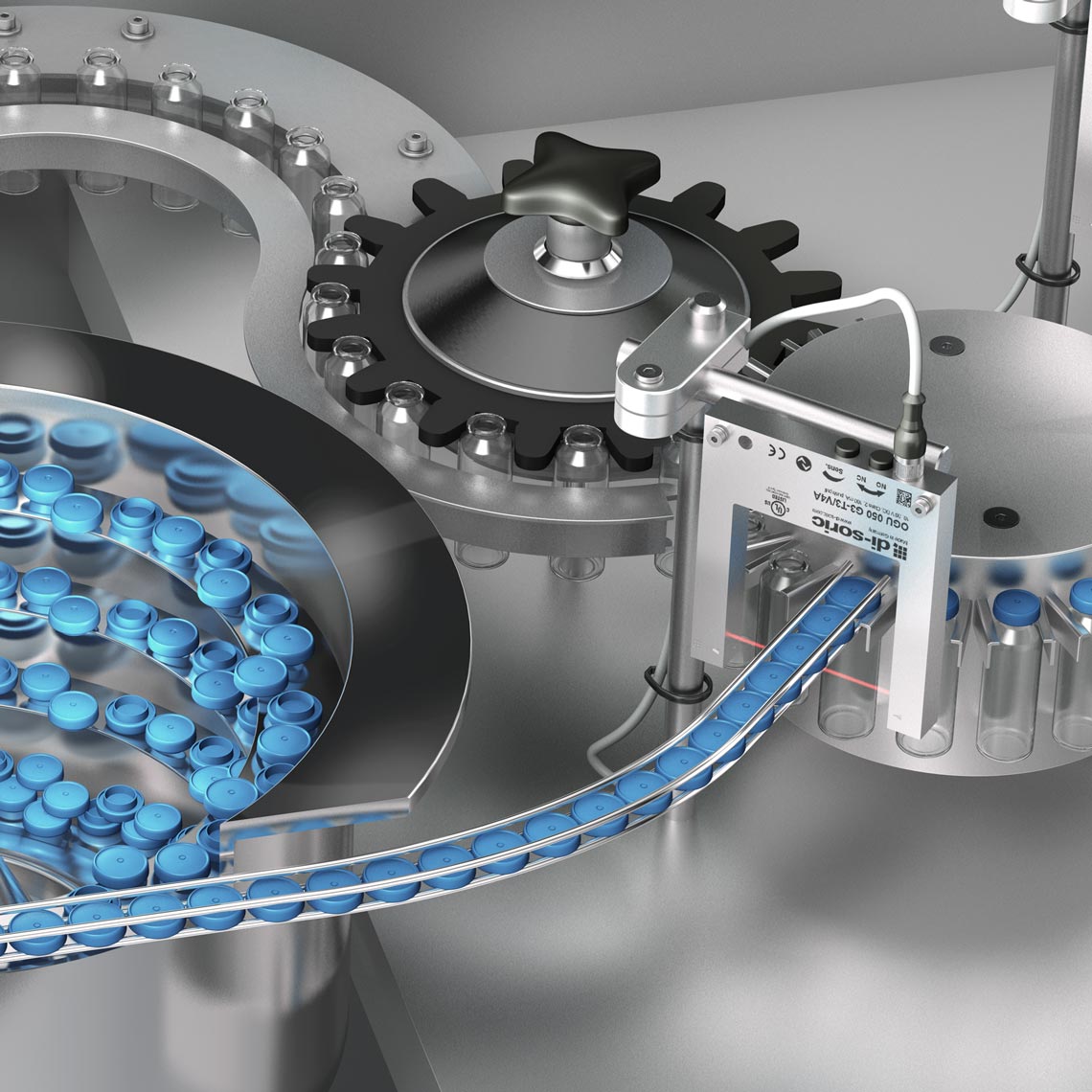

OGU Stainless Steel.

Practically indestructible.

For industrial environments requiring exceptional flexibility and high process reliability.

The OGU Stainless Steel sensors are especially well-suited to applications in packaging technology, the pharmaceutical industry, cosmetics industry and product feeding. Frequent batch changes and modifications to critical production parameters can be implemented easily and quickly using the IO-Link configuration.

Available fork openings:

30, 50, 80, and 120 mm.

Additional benefits of the OGU Stainless Steel fork light bariers in the V4A housing:

- Suited to areas with high standards with respect to hygiene and cleanliness

- Preferred field of application:

Packaging technology, pharmaceutical industry and cosmetic industry as trigger sensors or for controlling product feeding - Fast and precise, and therefore ideal for high-performance packaging machines

Additional benefits of the OGU Stainless Steel

fork light bariers in the V4A housing:

- Suited to areas with high standards with respect to hygiene and cleanliness

- Preferred field of application:

Packaging technology, pharmaceutical industry and cosmetic industry as trigger sensors or for controlling product feeding - Fast and precise, and therefore ideal for high-performance packaging machines

Application examples

OGU Stainless Steel

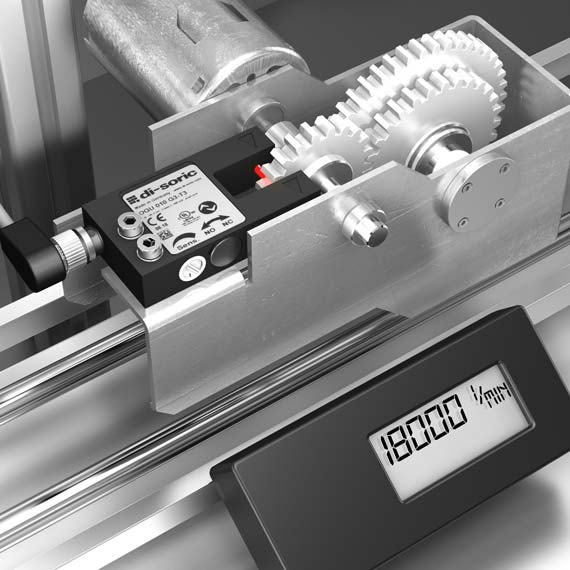

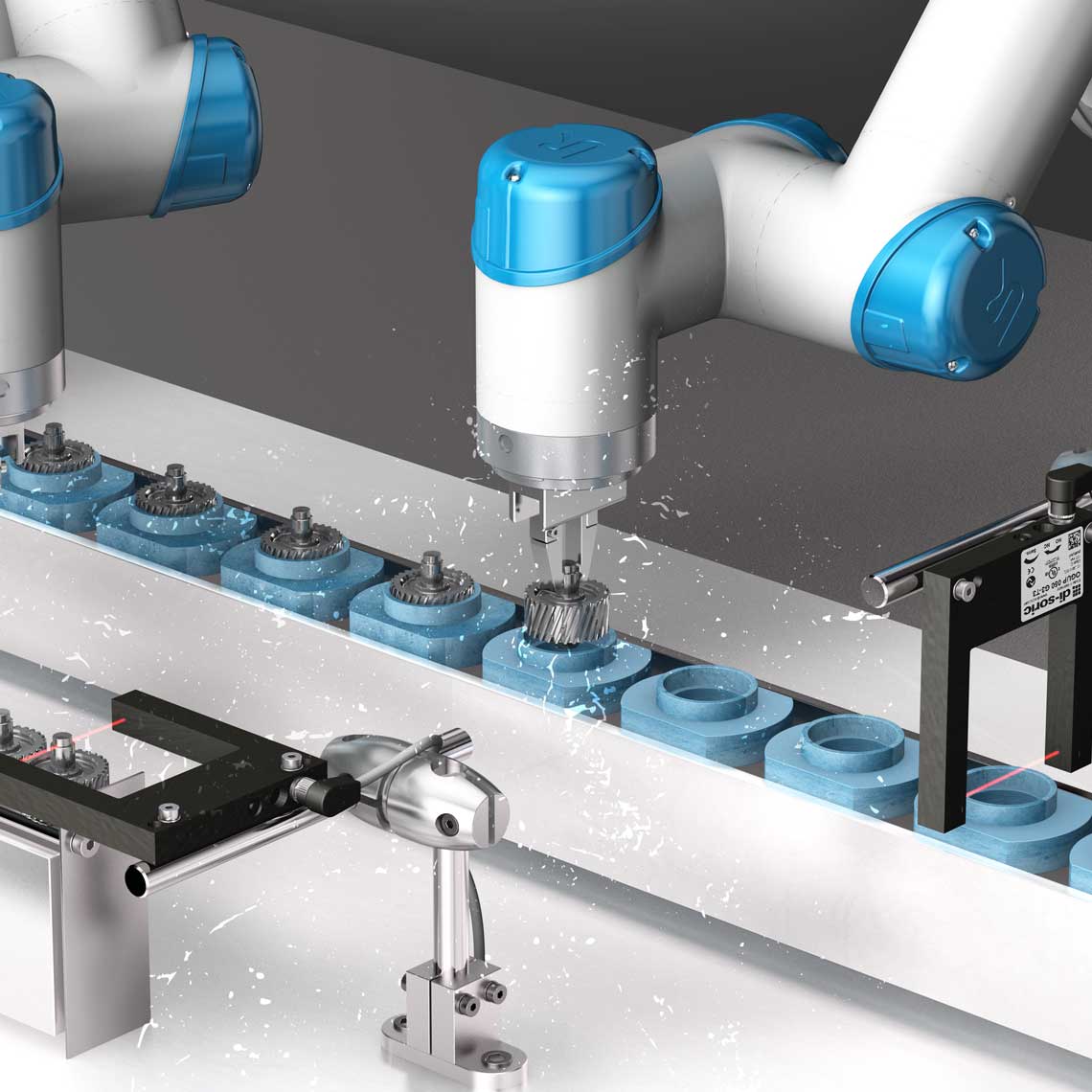

OGUP Dirt-resistant –

Our strong ones.

For when things get dirty.

Long after other sensors have given up, the OGUPs still have plenty of reserves left.

Available with fork openings of 20, 30, 50 or 80 mm, the OGUP series ensures precise object detection regardless of the surface, even in dirty and oily production environments.

With reproducibility of 0.03 mm, the fork light barriers offer a high degree of precision paired with maximum function reserve.

Additional benefits of the rugged OGUP infrared high-performance light barriers:

- Maximum function reserve while maintaining high switching accuracy

- Power sensor mode set by default; the Standard, High Resolution and Speed sensor modes can be freely selected

- Preferred field of application:

mechanical engineering applications involving large amounts of dust, coolant or oil

Additional benefits of the rugged OGUP

infrared high-performance light barriers:

- Maximum function reserve while maintaining high switching accuracy

- Power sensor mode set by default; the Standard, High Resolution and Speed sensor modes can be freely selected

- Preferred field of application:

mechanical engineering applications involving large amounts of dust, coolant or oil

Application examples

OGUP

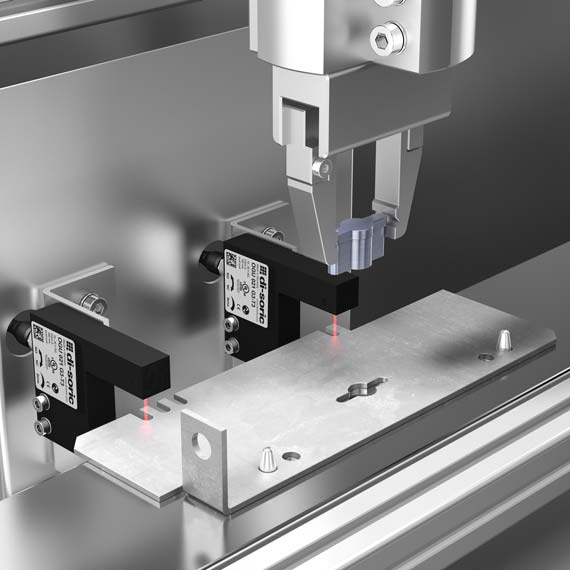

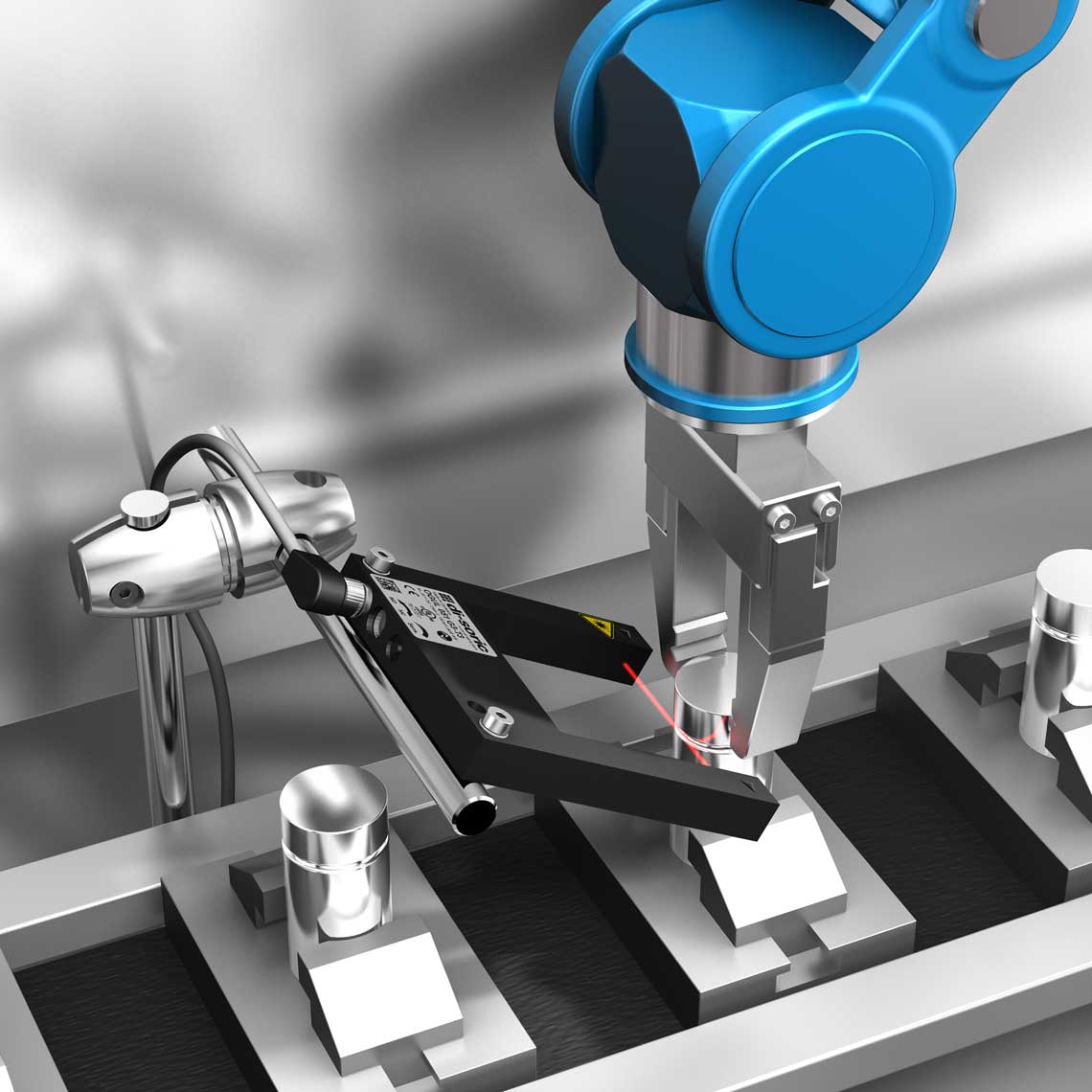

Maximum Precision:

OGUL Lasers.

Unmatched resolution.

Laser fork light barriers are used when the smallest parts must be detected.

The OGUL series available with fork openings of 30, 50, 80 and 120 mm is the best solution when the goal is process-reliable and fast detection of very small objects down to a size of just 0.03 mm.

With OGUL, the position and alignment of thin wires, drill bits or cannulae can effortlessly be defined down to a (reproducible) accuracy of 0.01 mm.

Additional benefits of the precise

OGUL Lasers / OGUL Laser Stainless Steel:

- Fast, reliable detection of the smallest parts with a high functional reserve

- 4 pre-configured sensor modes:

Standard mode is the default. The High Resolution, Speed and Power modes can be selected via IO link - Preferred field of application:

Detection of very small parts in assembly, handling and packaging technology, as well as quality control - Robust, powder-coated metallic housing or cleanroom-compatible V4A stainless steel housing for areas with strict requirements for hygiene and resistance to cleaning agents – both in the high protection class IP67

- OGUL lasers work reliably and with high process safety in a temperature range between –25 °C and 60 °C

For detection of the

smallest features.

Position and completeness monitoring in part feeding

Components must be checked for their position and completeness before they are fed to assembly machines.

For this purpose, di-soric has a wide selection of product solutions that increase productivity, minimize machine downtimes and even prevent machine damage.

Sample / Appointment

Download

Order and test samples now!

Test our fork light barriers and many other solutions free of charge and see for yourself for 28 days.